What is Condition Monitoring?

Condition Monitoring is a proactive maintenance approach that tracks the health of critical machinery and electrical systems by measuring parameters like vibration, temperature, oil quality, noise, and current flow. This continuous monitoring helps detect early warning signs of equipment deterioration, enabling timely maintenance before costly failures occur.

By shifting from reactive repairs to predictive strategies, condition monitoring reduces downtime, saves costs, and extends asset life, making it an essential part of modern industrial operations.

Why Condition Monitoring is Important

• Prevents unexpected equipment breakdowns and production losses.

• Reduces emergency repair and maintenance costs.

• Enhances the safety and reliability of plant operations.

• Provides real-time insights into asset performance.

• Improves equipment lifespan and operational efficiency.

• Forms the foundation of predictive maintenance programs.

Why Electrical Safety Audits Are Important

Add Your Heading Text Here

1. Vibration Analysis

• Detects misalignment, imbalance, bearing failures, and gear defects.

• Provides early warnings months before critical breakdowns.

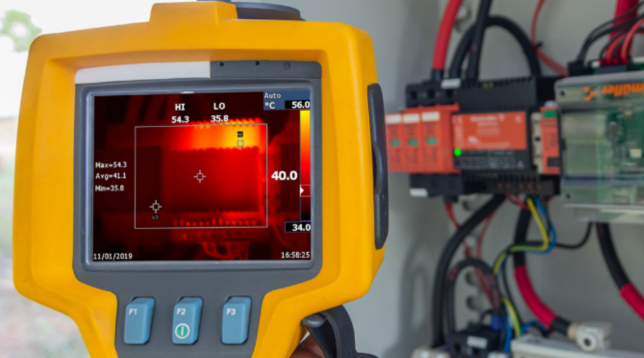

2. Infrared Thermography

• Identifies hotspots caused by loose connections, overloads, or insulation failures.

• Ensures both electrical safety and mechanical reliability.

3. Ultrasonic Testing

• Detects leaks, cavitation, and early bearing wear.

• Complements vibration and thermographic monitoring.

4. Oil Analysis

• Examines lubricant condition and contamination levels.

• Detects wear particles to prevent damage to gears and bearings.

5. Motor Circuit Analysis (MCA)

• Assesses motor insulation, phase balance, and winding integrity.

• Prevents motor-related failures while reducing energy consumption.

6. Electrical Monitoring

• Insulation resistance testing, surge testing, and current signature analysis.

• Ensures long-term electrical system safety and reliability.

7. Electromagnetic & Laser Techniques

• Detects cracks, internal flaws, and structural defects in conductive materials.

• Ensures critical components meet quality and safety standards.